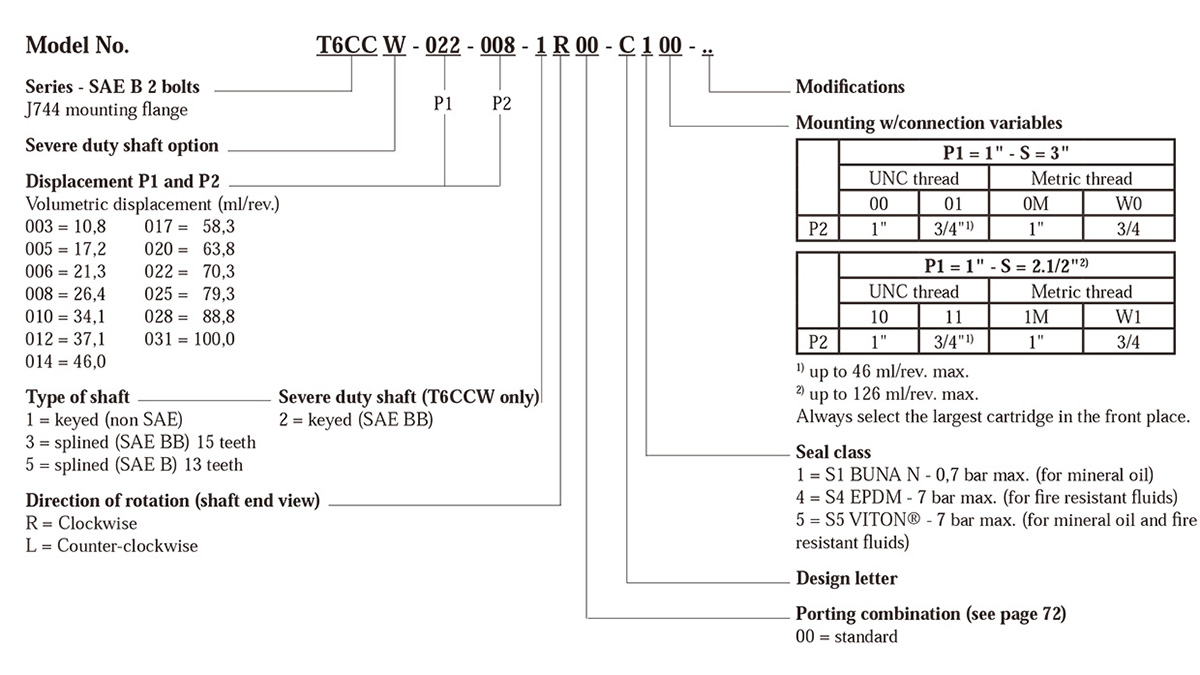

Máy bơm thủy lực công nghiệp áp suất cao Denison T6CC-025-017

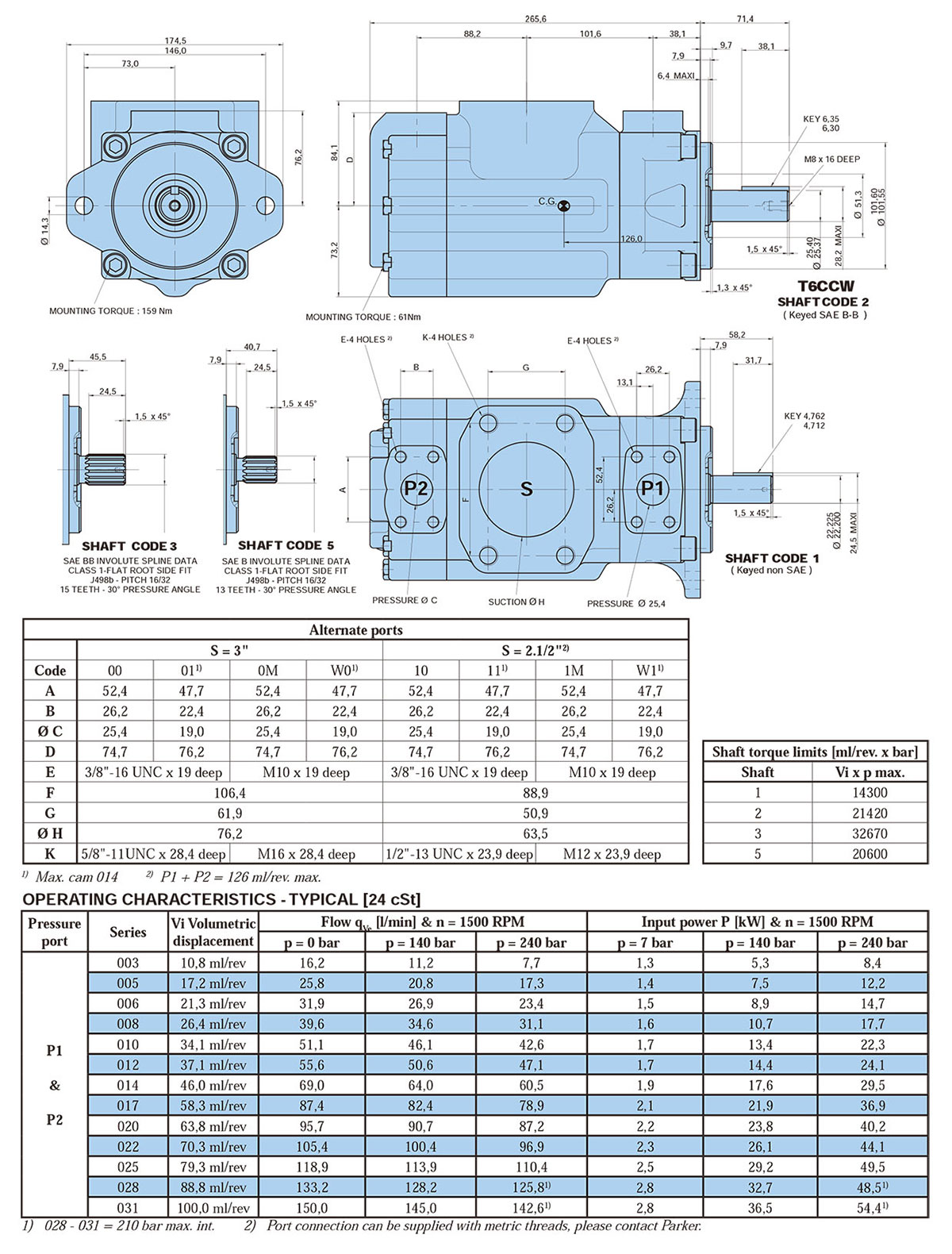

Industrial vane pump T6CC is a double pump with a rated pressure of 275 bar and a volumetric and mechanical efficiency of 0.94. The 12-vane design has a stable flow rate and is resistant to pollution, low noise, easy to install and maintain, and has a speed of 600-2800 rpm.

Mô tả

Tính năng

– High efficiency and high pressure: The T6CC vane pump’s structure is lightweight and compact, the power-to-weight ratio is high, the installation is flexible, and the rated working pressure is up to 275 bar, which can reduce the size of hydraulic actuators and pipelines and lower installation costs.

– Double high efficiency: The hydraulic vane pump’s volumetric efficiency and mechanical efficiency are both about 0.94, the energy loss is low, the system heat is reduced, and the operating cost is reduced.

– Double combination: Vane pump is composed of 025 and 017 displacement pump cartridges, and can provide a variety of flow combinations on demand; the 12-vane design makes the flow pulsation small, the output stable, and adaptable to different working conditions.

– Anti-pollution and balanced structure: The double-lip vanes enhance the ability to resist particle pollution, and the hydraulic balance design reduces shaft and bearing wear and extends the service life.

– Mother-and-child vanes + 12 vanes: The vane pump’s inherent low-noise structure is matched with an optimized design, the operating noise is low, and the working environment is improved.

– Flexible and convenient: The inlet/outlet oil port can be oriented in 4 positions, and the double vane pump has 32 installation combinations; the cartridge kit is separated from the drive shaft, and the pump does not need to be disassembled during maintenance, and the flow components can be quickly replaced on site.

– Wide speed range: This kind of industrial vane pump is 600-2800 rpm, suitable for low temperature conditions, low power consumption and no risk of jamming, stable and reliable operation.

Installation

– Cleaning inspection: Clean the installation surface and pipelines thoroughly to ensure that there are no impurities such as oil stains and iron filings. Check whether the various parts of the pump body are intact and whether the vanes of the hydraulic pump are flexible.

– Installation direction: Determine the inlet and outlet position according to the design requirements to ensure that the installation combination of the double vane pump (32 optional) matches the system.

– Oil selection: Use hydraulic oil that meets the specifications, and the viscosity and cleanliness must meet the standards. Filter the oil according to the requirements of the manual to avoid contamination and wear of the vane pump vanes.

– Direction and speed: Confirm that the motor direction is consistent with the hydraulic pump logo, and the speed is controlled within the range of 600-2800 rpm. Preheat the oil when starting at low temperature to prevent jamming.

– Initial start: Fill the vane pump with hydraulic oil before starting, drain the air in the pipeline, run at low speed for 5-10 minutes, check for abnormal noise, leakage or overheating, and gradually increase the pressure after the hydraulic system stabilizes.