Pompa idraulica a doppia palette Parker serie T67DC da 280 bar all'ingrosso OEM ODM

The T67DC-B42-031 industrial vane pump’s 280 bar maximum pressure, 94% efficiency, ±2 bar pulsation and dual-vane, modular pump structure make it an ideal choice for high-pressure, energy-saving, high-precision and low-noise applications, taking, easy maintenance.

Descrizione

Caratteristica

1. High pressure and high efficiency design

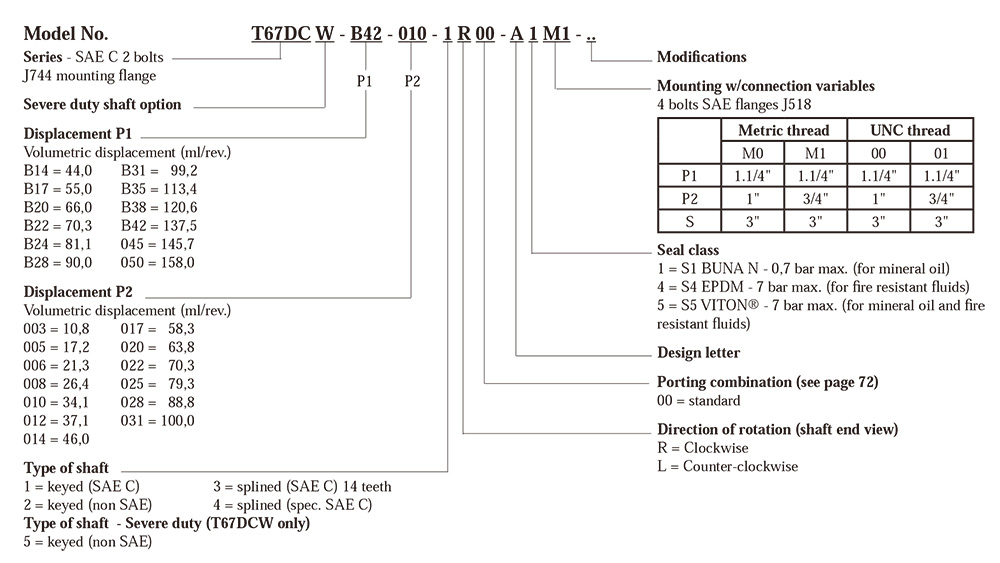

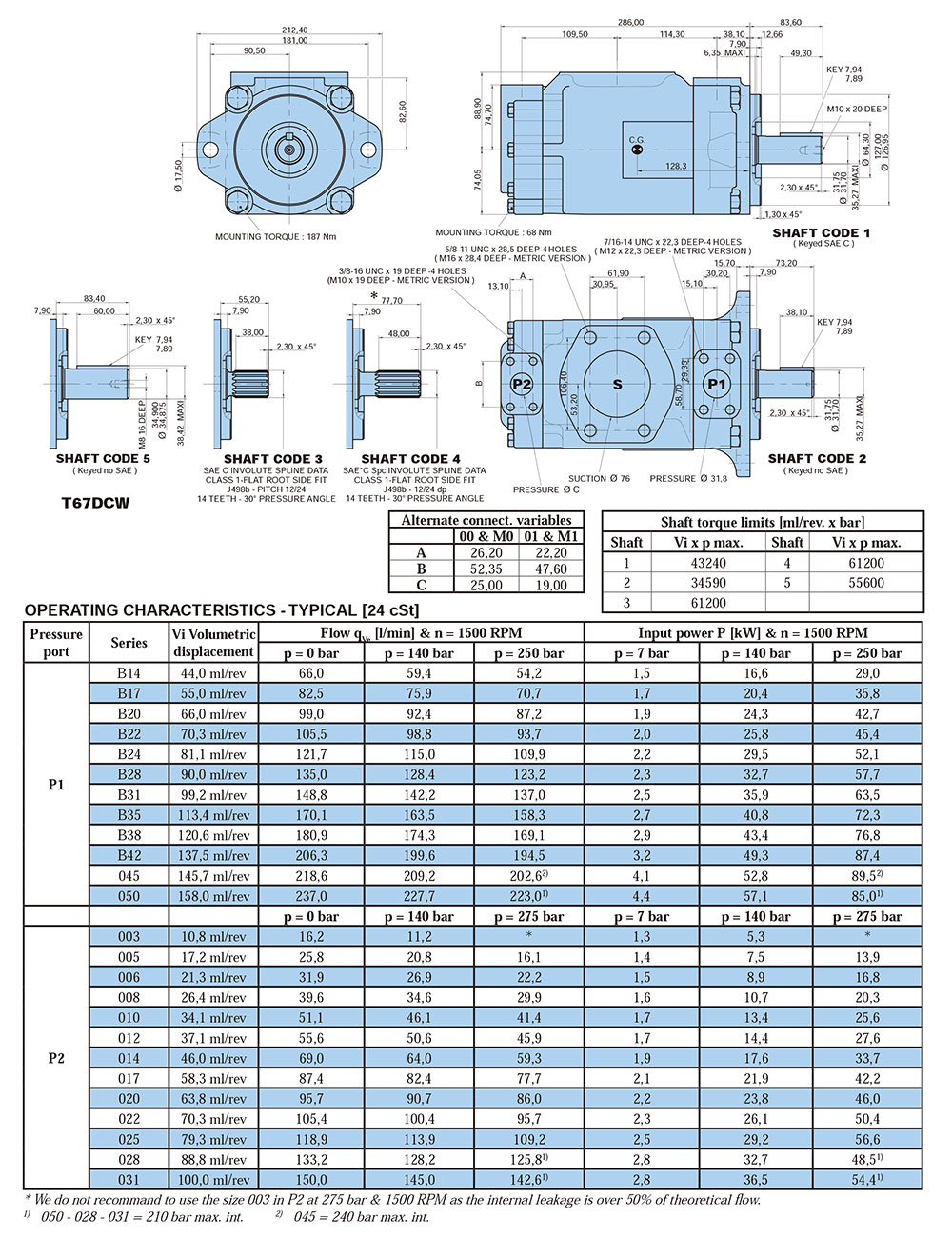

The vane pump adopts a double-vane structure design, with a main pump cartridge displacement of 42cc/rev (B42) and a secondary pump cartridge displacement of 31cc/rev (B31). Its maximum working pressure can be regarded as 280 bar, and therefore it is fit for high-output pressure equipment such as industrial machine tools and heavy equipment. The volumetric efficiency and mechanical efficiency are both above 94%, reducing energy loss and system heating, and the speed can be as low as 600 RPM, which is suitable for energy-saving or low-speed and high-torque scenarios.

2. Low noise and anti-pollution ability

The hydraulic pump controls the pressure pulsation within ±2 bar, which deeply reduces both pipeline vibration and noise. The dual-vane technology adopted enhances the ability to resist particle contamination, able to adapt to harsh working environments and reduce wear and failure due to impurities.

3. Wide speed range and fast response

T67DC supporting a speed of 600 to 3600 RPM provides flexibility to match the output characteristics of different power sources, namely motors or engines. Its fast response capability to pressure cycles, such as changes between high and low pressure circuits, is built to achieve flow repeatability error of less than 1.0%. This indicates a high level of control accuracy is supported in the cases where machine tools or automated production are included.

Maintenance

– High anti-pollution ability: The T67DC vane pump has a double-lip design of the vane, which can be used to improve the seal between the vane and stator and improve particle pollution resistance.

– Simple to maintain: Because the T67DC hydraulic pump is based on the modular design, all you have to do when maintaing it is to remove the pump core assembly from the pump housing for inspection, repair or replacement. In addition, the connection between the various components of the T67DC pump is simple, which is easy to disassemble and install.

-Oil cleanliness requirements: The oil cleanliness level is required to reach ISO 4406 18/16/13, that is, the solid particle size ≥5μm and the content ≤1280/mL are allowed, and it is suitable for NAS 8-level filtration system. Users need to regularly check and replace the hydraulic oil filter to reduce the wear of impurities on the internal components of the pump.

-Regular maintenance items: including regular inspection and maintenance to check whether the mounting bolts of the vane pump are loose, whether the oil level and quality are normal, whether the filter is blocked, and whether the operating sound and temperature of the pump are abnormal.