Company Profile

JINPINLUB is a brand that provides high-performance vane pumps, hydraulic valves and power units, integrated blocks and complete hydraulic system solutions to customers around the world. Our R&D and production team has been established for more than ten years. The production workshop is equipped with CNC machining centers, precision testing equipment and intelligent assembly lines, and strictly implements production processes and quality control standards. We understand your product needs very well and have experience in serving tens of thousands of customers.

Main Products

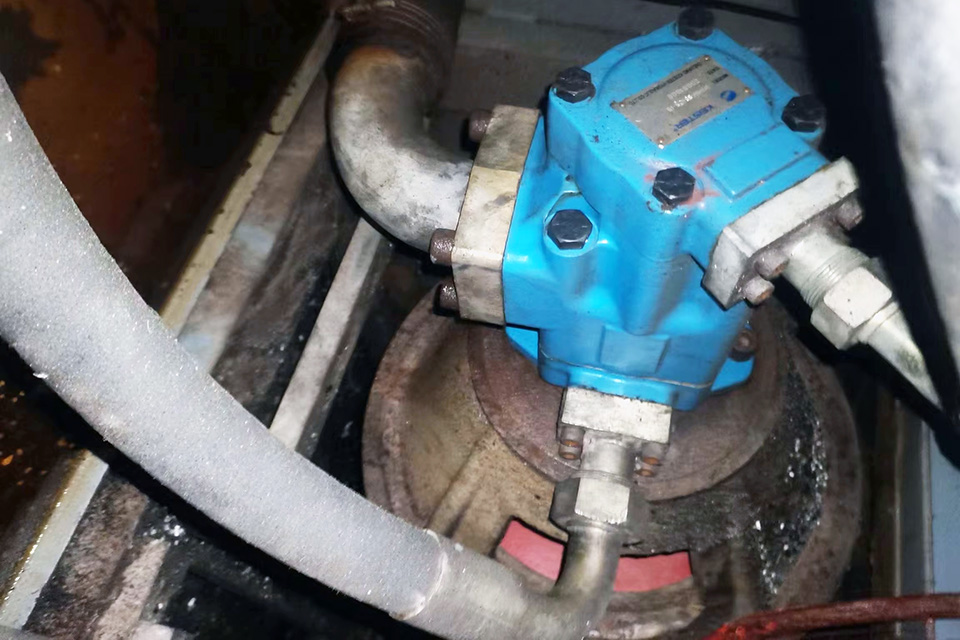

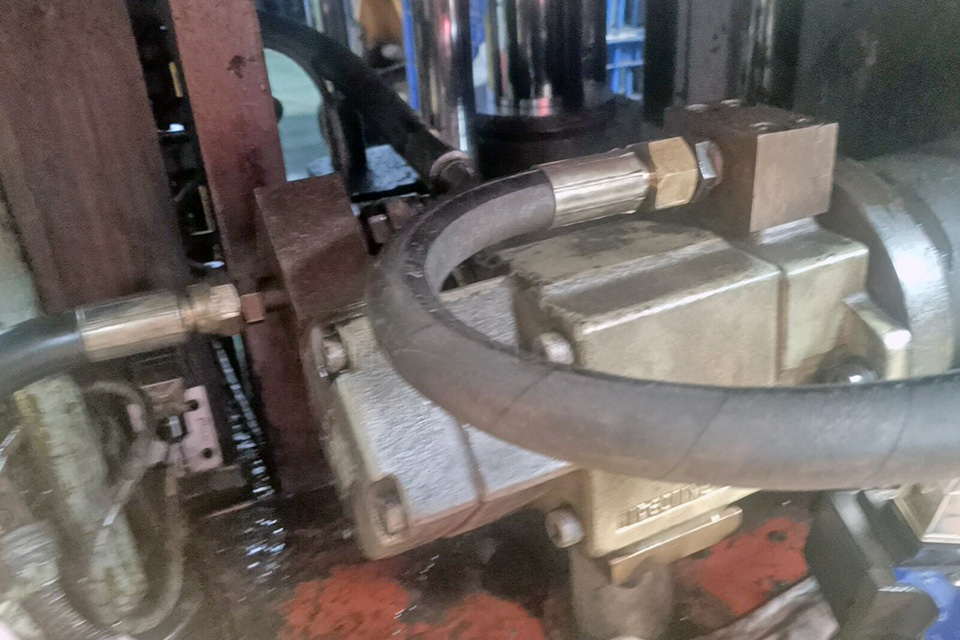

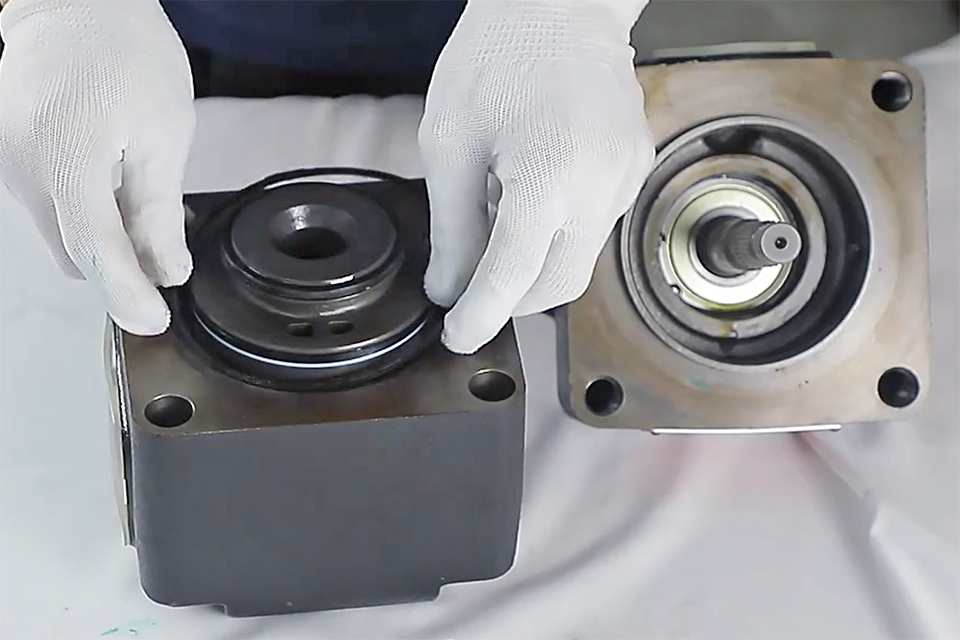

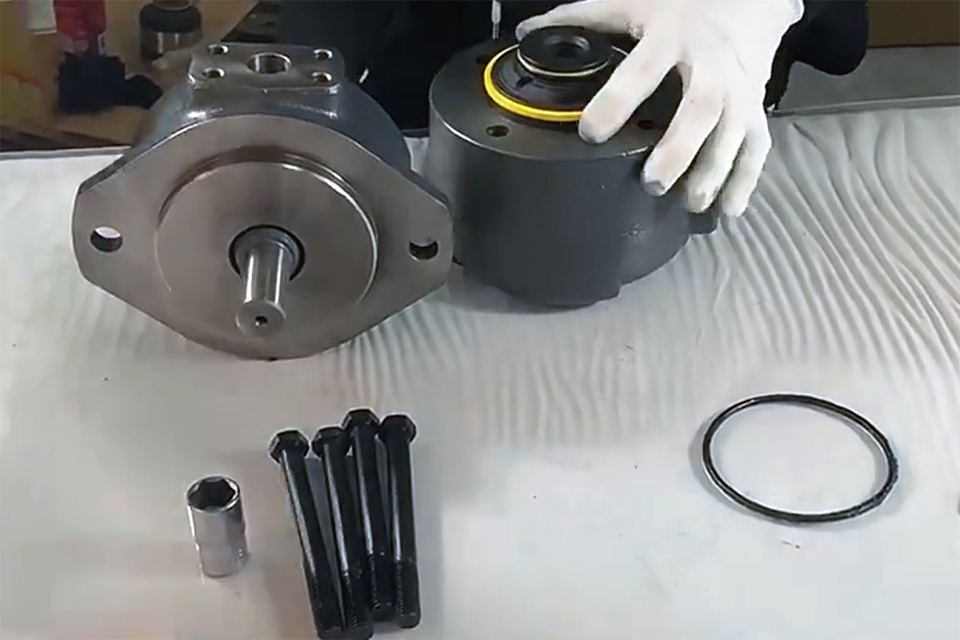

Our products mainly include piston pump, vane pump, gear pump, hydraulic motor, and other hydraulic accessories. JINPINLUB focuses on Yuken PV2R, KCL VQ, Parker Dennison T6/T7, Vickers V/VQ, Tokyo Keiki SQP, and vane pump components. The products have been tested by authoritative departments, and various performance and technical indicators have reached the standards of leading pump manufacturers. Low noise, high volumetric efficiency, long service life and high cost performance are the main advantages.

Technical Team

Our technical team consists of mechanical, electrical, hydraulic design and material experts, focusing on the innovation and optimization of hydraulic systems. The production team ensures that the products meet international standards from raw material selection to process optimization. At the same time, strict quality control testing guarantees the performance and reliability of each hydraulic pump. We actively participate in the exchange of hydraulic pump industry, improve professional level through technical seminars and forums, and promote the development of the industry.

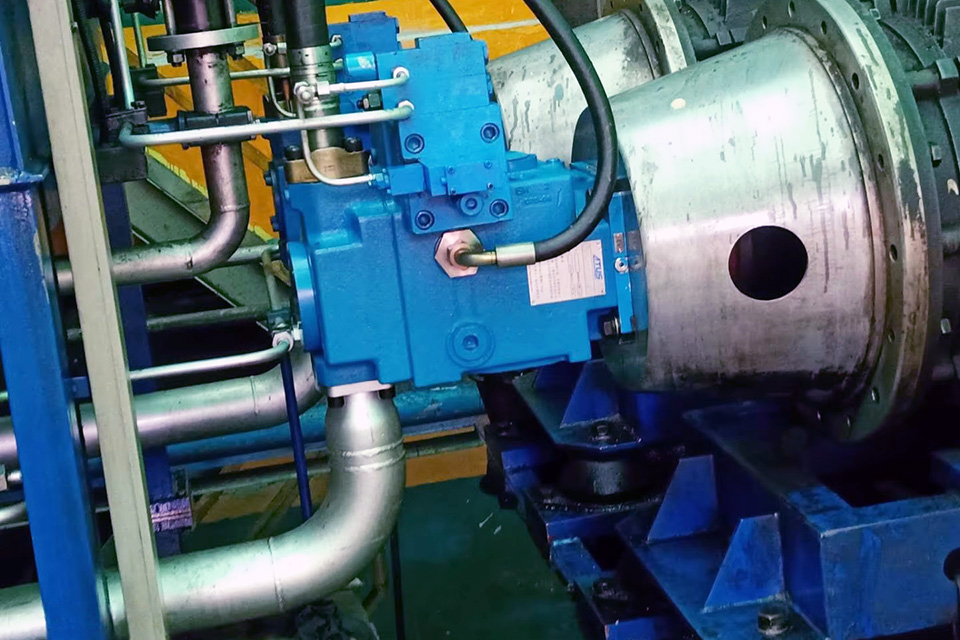

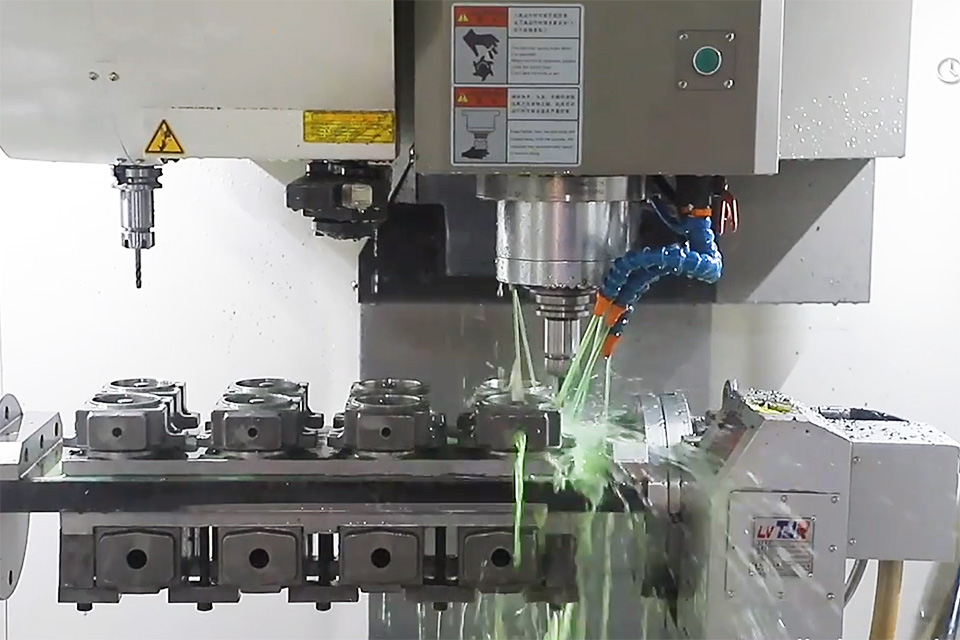

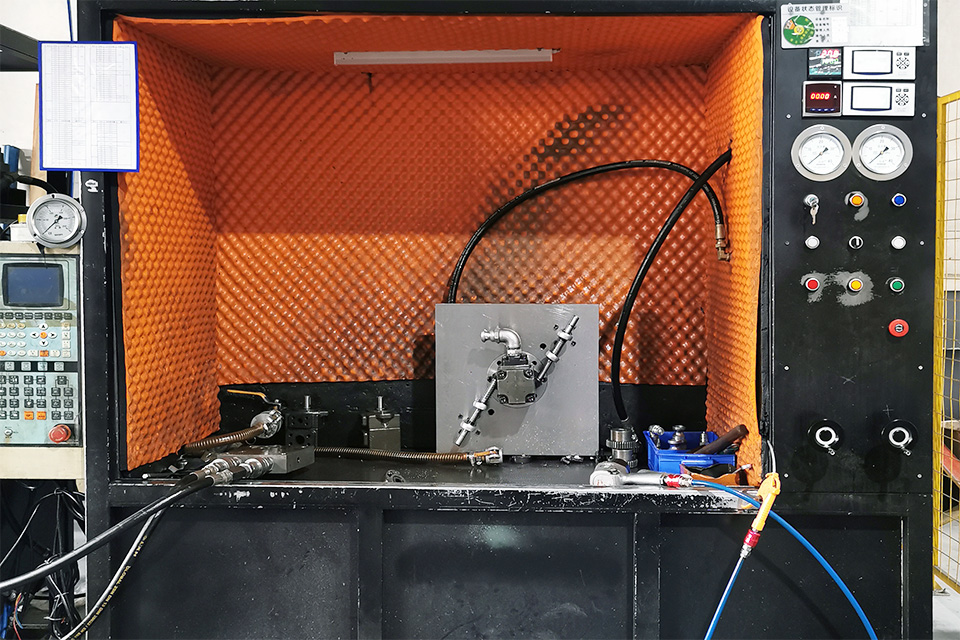

Manufacturing Machine

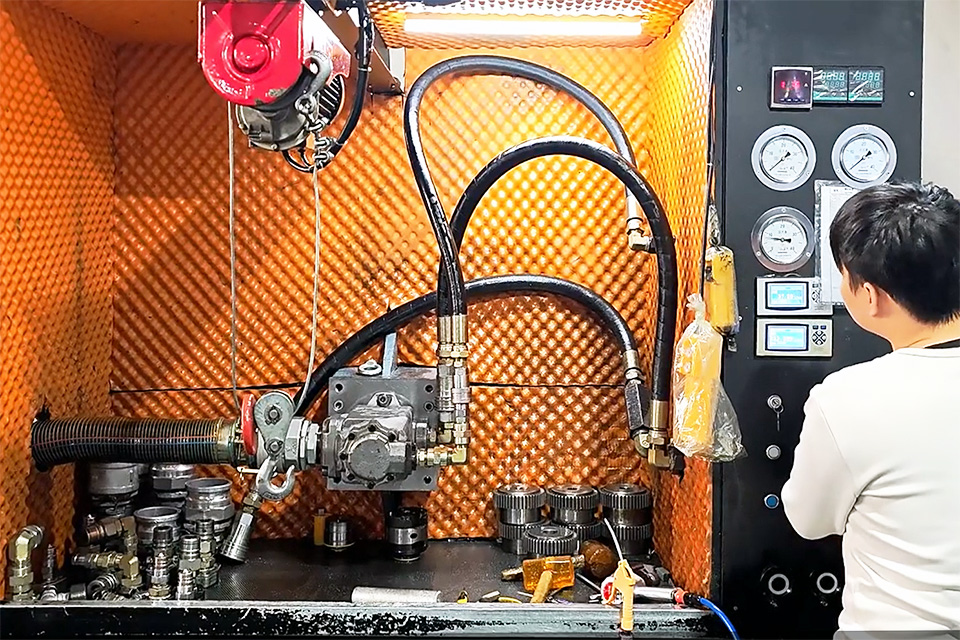

Our production team has a production workshop area of more than 3,000 square meters and more than 30 advanced manufacturing equipment such as various machining centers and testing machines, such as: CNC machine tools, CNC grinders, laser cutting machines, broaches, gear hobbing machines, gear shaping machines, grinders, honing machines, ultrasonic cleaning machines, heat treatment equipment, coordinate measuring machines, projectors, pneumatic instruments, hardness testers, surface finish testers, spherical testers, metallographic analyzers, etc.

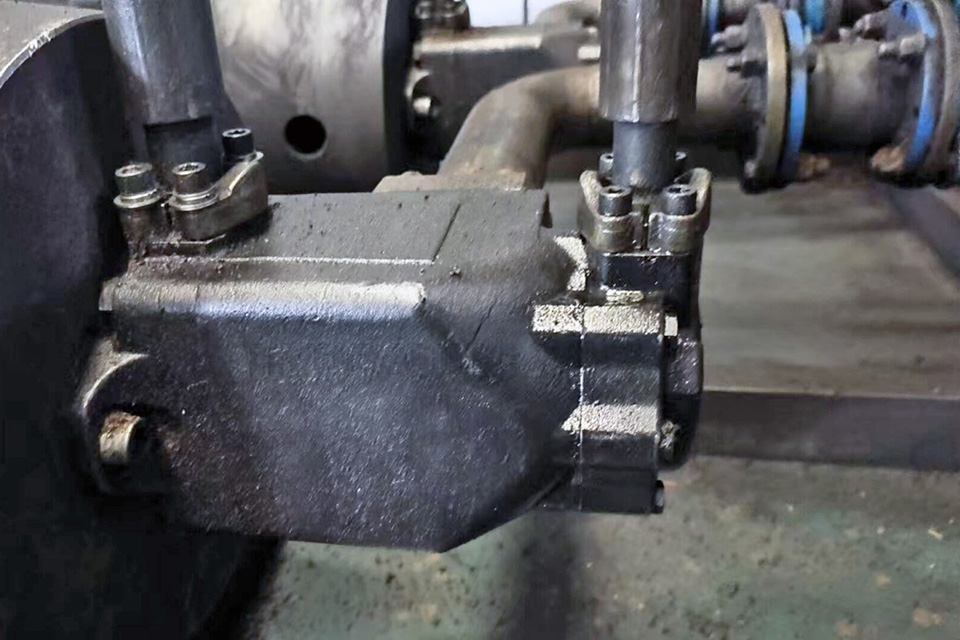

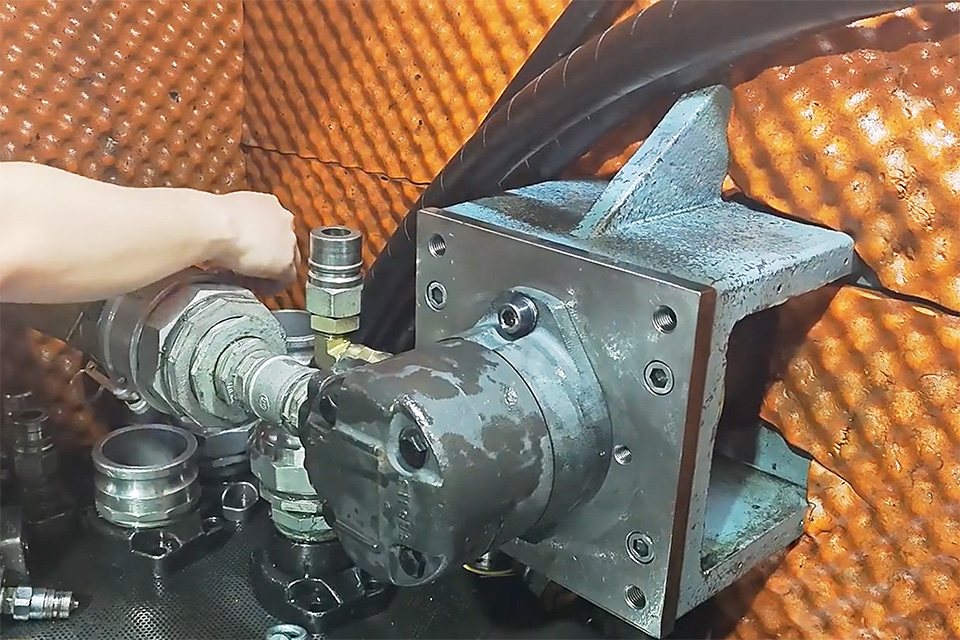

Quality Control

In raw material selection, we work together with better suppliers and strictly control the wear-resistance, anti-corrosion and mechanical strength of materials. Testing process of finished products is very strict, like pressure test, flow test, durability test and simulated long-term use test to make the hydraulic pump operate steadily under various conditions. Quality control team also makes periodic updates to the testing process and improves product reliability as per customer feedback. We ensure every hydraulic pump is of superior quality, meets industrial application standards, and enhances customer confidence.

Business Partners

Our vane pump hydraulic systems are used in various industries such as construction machinery, agricultural equipment, manufacturing sector, energy industry, ships and aircraft. In the global market, our company and personnel have been catering to tens of thousands of clients with hydraulic pump associated services. The Asia-Pacific region has been one of our most valued markets with the highest growth rate due to huge demand for infrastructure and industrialization. We will also enhance the performance of products so that hydraulic pumps become efficient, stable and durable under various operating conditions, and provide efficient hydraulic solutions to customers globally.