- The connection between vane hydraulic pumps and vane hydraulic motors

Both realize energy conversion based on “volume change”. The vane hydraulic pump drives the rotor to rotate through external power, and uses the reciprocating motion of the blades in the rotor slots to make the sealed volume change periodically, converting mechanical energy into hydraulic energy; the vane hydraulic motor relies on the input pressure oil to push the blades and drive the rotor to rotate, realizing the conversion of hydraulic energy to mechanical energy. The essential logic of energy conversion between the two is the same.

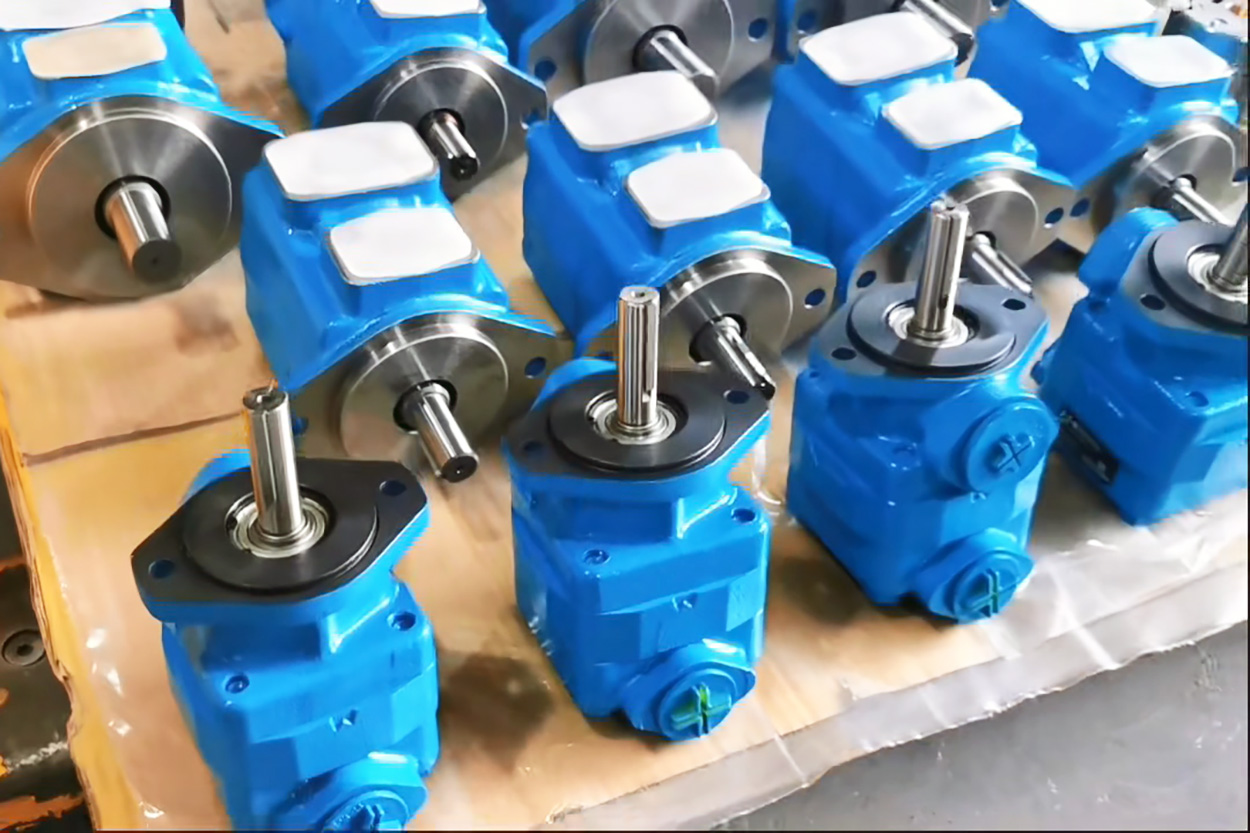

In terms of structural composition, their core components are highly similar, including rotors, stators, blades, oil distribution plates and housings. Among them, the internal contour curve design of the stator needs to meet the sliding requirements of the blades, and the sealing cooperation between the blades and the oil distribution plate is basically the same. These common structures ensure the sealing performance and working efficiency of the components. In addition, in the hydraulic system, the pump and the motor play complementary roles: the pump outputs pressure oil as a power source, and the motor consumes pressure oil as an actuator to output rotational mechanical energy, and together build a complete energy transfer system.

- The difference between vane hydraulic pumps and vane hydraulic motors

The energy conversion direction and application scenarios are the most intuitive differences between the two. Pumps use mechanical energy as input and hydraulic energy as output, and are often used in power supply scenarios such as machine tool hydraulic stations and injection molding machines; motors use hydraulic energy as input and mechanical energy as output, and are mostly used in execution links that require rotational motion, such as excavator turntable rotation and printing press roller drive.

In terms of structural design, the two have targeted optimizations. In terms of the oil distribution plate, the pump’s oil suction and oil pressure windows are fixed, and negative pressure oil suction is formed by speed; the motor’s oil distribution plate window is symmetrically designed to meet the needs of forward and reverse rotation, and some are also equipped with pre-tightening oil grooves to ensure that the blades fit the stator when starting. The blades are installed at different angles. To reduce friction, the pump is often tilted forward by 10°-14° and the rotation direction is fixed. To achieve bidirectional rotation, the motor blades are mostly radially installed or symmetrically tilted. There are also differences in the oil leakage method. The leaked oil of the pump can flow back through the internal channel, while the motor requires an independent oil leakage port to prevent excessive pressure at the bearing and seal.

There are also significant differences in working characteristics and performance requirements. With respect to speed, the pump needs a certain speed to achieve the oil suction effect, but speed that is too high is easy to cause cavitation, and a good low speed start torque and wide speed range is expected from the motor. In terms of efficiency and pressure, the rated pressure of the pump can reach 6.3-21MPa, and volumetric efficiency also is as high as 90%-95%, and it represents more of a concern for flow stability, the rated pressure of the motor is slightly lower ( 6.3-16MPa), but the total efficiency is around 80%-90%, and it primarily is aimed at torque pulsation suppression. In terms of flow and torque relationship, the pump output flow is positively correlated with the speed, the motor output torque is proportional to the pressure difference (T=Δp×V/2π), and the speed is related to the input flow.

Although in theory some vane pumps can temporarily act as motors, the lack of dedicated oil drain ports and fixed blade inclination angles will lead to low efficiency and insufficient reliability. Vane hydraulic motors usually need to be specially designed through symmetrical structures, preload mechanisms, etc. to meet actual working conditions.