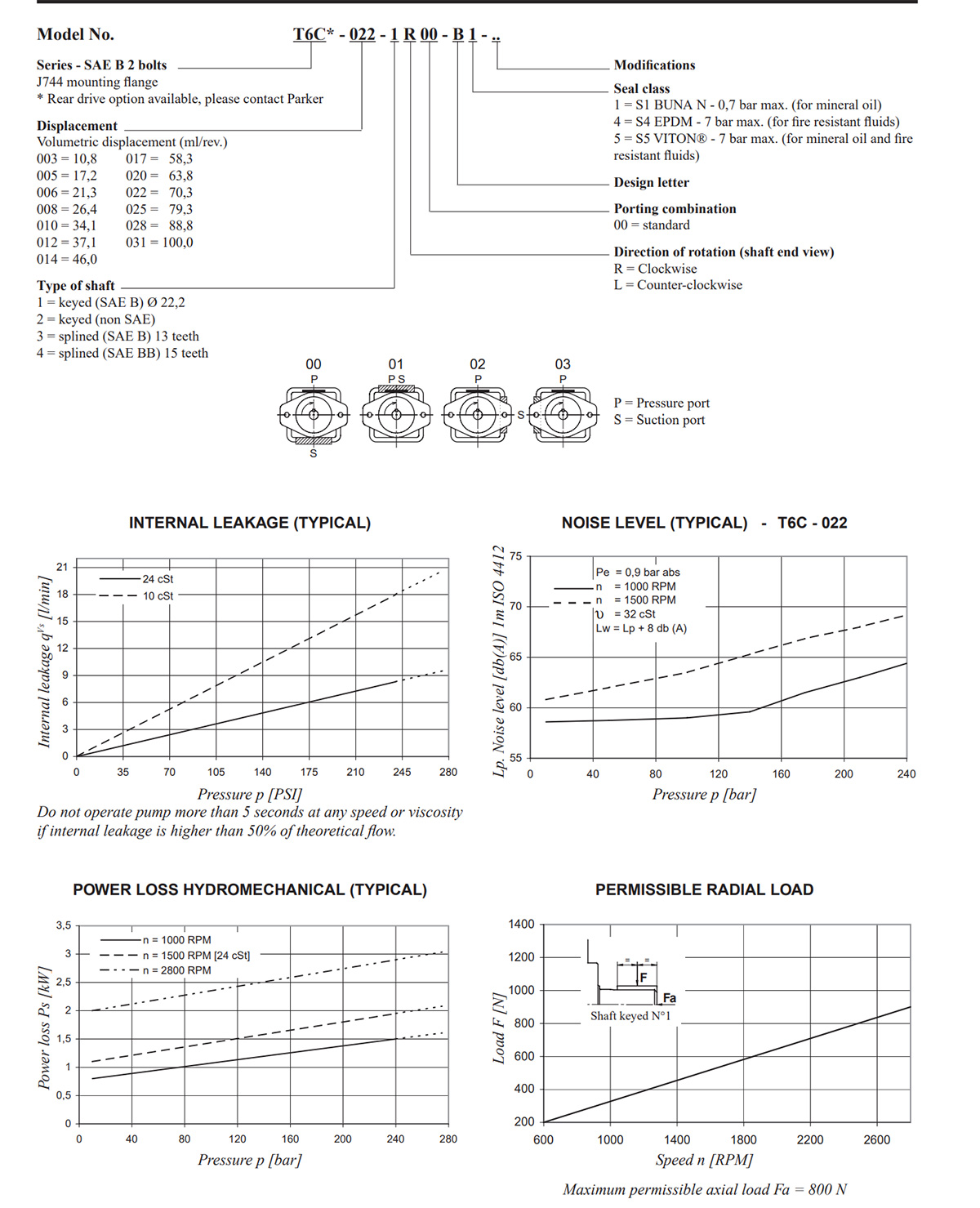

275 bar Hydraulic vane pump T6C single oil pump for die casting machine

The T6C series single vane pump manufactured by Denison is a high-end hydraulic pump that introduces the new “modular” concept.In industrial hydraulic systems, the T6C can provide a high pressure, low noise, high efficiency alternative.Compact size, modular design and flexible mounting options make it an excellent option for several applications.

Description

Feature

The T6C series single vane pump is a high-performance hydraulic pump from Denison. It has a modular design, and it can be used in high-pressure, low-noise, and high-efficiency industrial hydraulic applications. It’s compact structure and flexibility for installation have made it useful for metallurgy, injection molding, engineering machinery, machine tools and other applications.

Performance Characteristics:

Vane pump has high working pressure: rated pressure is up to 275 bar (max 310 bar), and suitable for high-load conditions.

Industrial hydraulic pump has high volumetric efficiency: typical volumetric efficiency is 0.94, and remaining stable under high pressure keeps power consumption lower and heat generation down.

Wide-range of speed: standard type can achieve 600-2800 rpm; vehicle type can be as low as 400 rpm to meet any equipment configurations.

T6C vane pump has low noise features: small pulsation of pressure (about ±2 bar), can significantly reduce noise of the hydraulic system, and provide better stability of the hydraulic system.

Good anti-pollution ability: with the double-lips structure blades, the vanes can better withstand oil contamination before causing harmful results to the pump and extend the lifespan of the pump body.

Notes

1. Before starting the T6C single pump, one must put some clean hydraulic oil into the pump body and fill it up.

2. Check that the direction of rotation of the single vane pump is consistent with the arrow for rotation direction indicated by the motor.

3. During start-up of the hydraulic pump for the first time or after a long shutdown, it sometimes may be hard to absorb oil for the hydraulic pump. Hence, an exhaust valve should be installed at the outlet of the pump or the oil outlet pipe joint should be loosened for exhausting the air. It should try to be started under no-load conditions.

4. The air mixed in the pump and pipeline would do noise and vibrations. Therefore, they should repeatedly do no-load starts and stops of the pump to exhaust air.

5. For oil pumps with servo motor drive, low speed should be selected first for the motor (pressure mode is switched to speed mode) from the servo driver, and the motor shall be run at low speed for about 3-5 minutes to exhaust the air and then could be switched back to normal speed after the oil pump has sounded normally.